This week the team saw significant progress in the undergoing project. We were able to meet the budget requirement for the project and got an approval by our supervisor for a substantial amount of GHs 1500. Thus, the team can progress to the procurement of all the necessary materials and equipment needed to successfully implement the first stage of the project: the testing phase.

The testing phase will involve employing two methods of mixing the plastic constituents. These include;

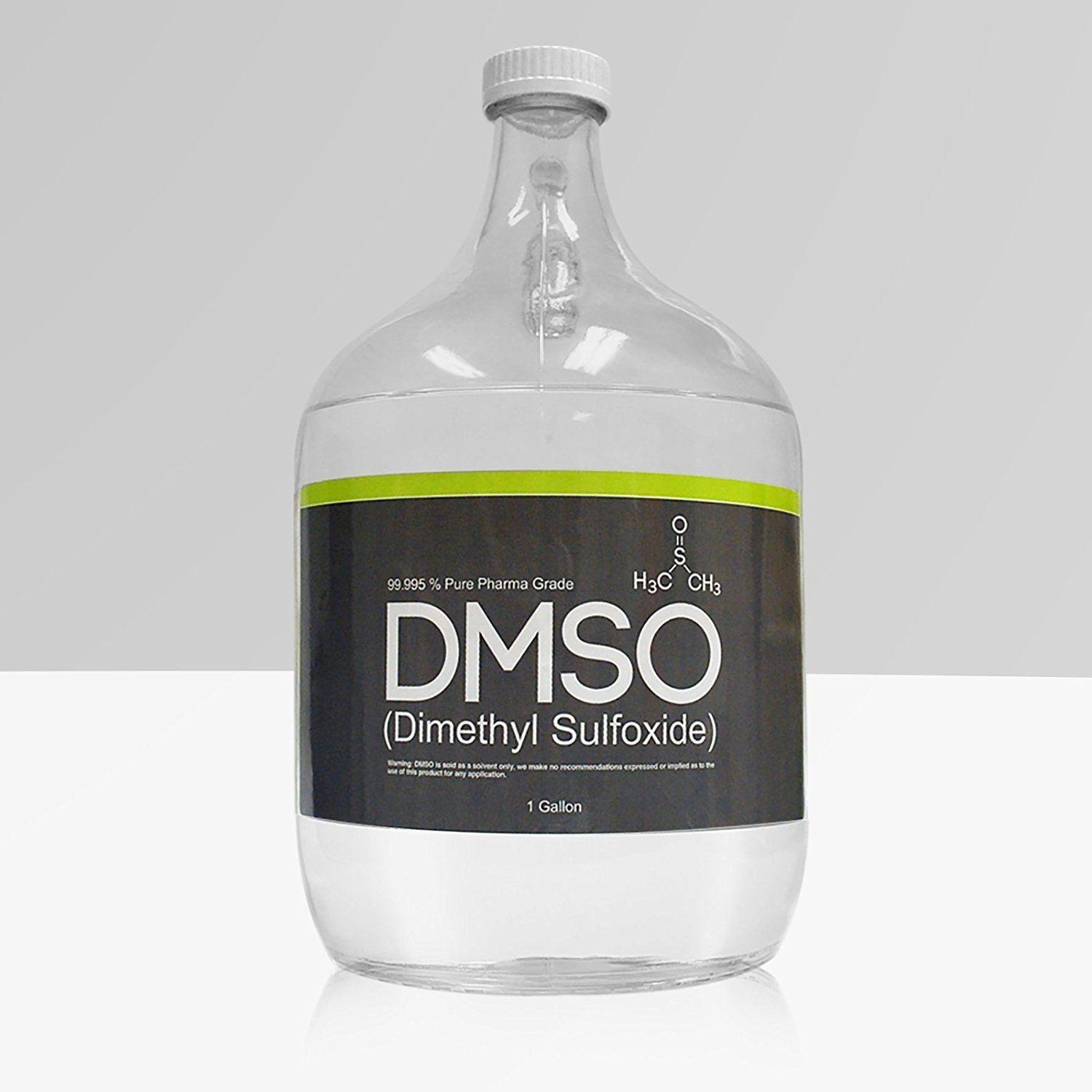

1. Dissolving the constituents in special chemicals (acetone or dimethylsulfoxide) to form a uniform mixture.

2. Melting the constituents over a suitable flame to form a uniform mixture.

Photo credit :https://www.ecochem.co.nz/order-chemicals/chemicals/acetone/

Photo credit : https://www.amazon.com/DMSO-Special-99-995-Dimethyl-Sulfoxide/dp/B01BUA51KC

These tests would be made to deduce the most effective and cost efficient method of producing quality road material composites for the long standing benefits of lasting roads within our country, Ghana. Completion of this phase will forge the team ahead in implementing the novel mixture on the Ashesi road. This process will specifically involve filling potholes with the composite mixture. Thereafter subsequent observational tests will be done using sensors to check the tensile strength of the composite over time.

Finally, we still hold on to our goal of commercializing this road composite product for the improvement of the quality of roads in Ghana (whiles reducing the volume of plastic waste materials).